Writing Compliant WPS (and why it’s important)

Most of you will recognize that a WPS is a document which carries quite an important role in the welding industry. Your company’s clients, depending on the scope of the project and the trust they have in your work, might not accept that you start welding before you present them.

So it is an important document that carries very sensitive information. After all, this document will reflect your final product, as it tells exactly how a welder should perform his duties on the finished piece.

And sometimes this is why a project takes a week or two before it starts

The full welding book with all the welding procedure specifications has to be fully approved by the client and 3rd party inspector before you can start welding, so the welding engineers begin this process of writing WPS, and it goes something like this:

- Project bid is won by your company

- After verification of the detailed capabilities to fulfill this project, a welding book is started

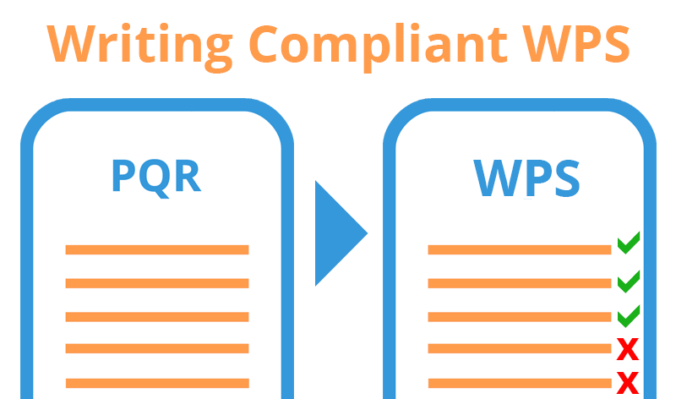

- The welding engineer will look to all the PQR that are available and qualified to do the project

- Writing of the WPS, based on the PQR/standard and project requirements

- Inclusion of all the weld types, WPS, PQR and weld maps into the welding book

- Sending the welding book to your client and 3rd party inspector for approval

- Reviewing process sends back with corrections to be made

- Repeat steps 4 to 8 until client approves

This reviewing process could be repeated quite a bit of times, as new mistakes and remarks might be discovered on the 2nd and 3rd review.

So, while the remarks will be hard to avoid (there’s always the chance that the client has some new additional information that wasn’t mentioned before), the mistakes can be mitigated.

We have taken up the challenge to solve this problem ourselves.

In my own experience, this was an issue, and one of my clients for WeldNote suggested that we think about a way to validate any WPS you are writing with the information from the PQR.

And so we did…

WeldNote now compares all the information from the approval ranges of the PQR with the information you input on the WPS, and this has improved the quality of engineer’s who work with our software, rather than copying and pasting information from different word or excel documents, the information is guaranteed to be correctly input from the PQR.

The WPS smart writing is just one of the ways that software could improve the welding industry.

Rather than just being tools for storing information, softwares should be smarter, so that they can actually make engineers’ life better, which is something we are working hard at.

But there’s more

Our software already allows you to search for what you have qualified and provides reminders for welder certificates, as well as writing welding books for your projects, but we are going one step further and including a full traceability control and weld logs tool, embedded in WeldNote with full interaction with all other features.

And for this one, I would like to spark some discussion! From your experience, what is the key information that should be included in the final reports to send to your clients?

Please reply to @weldnote, our facebook or linkedin

Thanks for reading!

-Tiago Pereira, CEO at WeldNote